The Thermal Suit project aims to provide thermal feedback on the user's virtual environment. If the user is in an Antarctic application, the suit will provide cold; if he's in the Sahara, the application will provide heat. Vibrating motors will also be added to make the suit even more immersive.

Introduction

Our research will focus on providing a global or environmental thermal feedback. Unlike much of the existing work, which primarily focuses on gloves that deliver localized thermal feedback on specific materials, our aim is to create thermal sensations that encompass the entire body. This approach will enhance the sense of immersion by simulating temperature changes that align with the user’s environment in a more holistic manner. The work presented here is based on Peltier technology, which allows for precise and compact temperature control, effectively providing both heating and cooling capabilities.

Modular Thermal Module Design for Haptic Vest

To realize this project, we adopted a modular approach. Each temperature module must be independently controlled and powered to ensure interchangeability. In this section, we will discuss the thermal module that will be replicated to create the haptic vest.

At the core of our thermal module is a Peltier element. Specifically, we selected the 12V DC TEC1-12706 Peltier module, which has a power rating of 51.4W. This module offers a good balance between power and safety; a module that is too powerful could potentially harm the user in the event of a control failure. To drive this module, we used an L298N dual H-bridge driver. This driver supports a voltage range from 5 to 35V, which makes it suitable for our 12V requirements. The maximum current per channel of the driver is 2 amperes, so we connected both channels of the driver to a single Peltier element to achieve the required 50W power. Each Peltier element is controlled by a dedicated L298N driver, which allows precise control over the power supplied to the Peltier element as well as the direction of the current, enabling both heating and cooling of the user-facing side of the module. Each thermal module is equipped with an Arduino Nano to control the L298N driver.

To provide a quick visual indication of the module’s status, four colored LEDs were added. The yellow LED illuminates when the module is powered. The green LED lights up when the module is idle, meaning that it is neither heating nor cooling (this may occur when the module is at the target temperature within a tolerance of one degree, or when no command has been given). The red LED is activated when the module is heating, indicating that the target temperature is higher than the current temperature of the module. Finally, the blue LED lights up when the module is cooling, indicating that the target temperature is lower than the current temperature of the module.

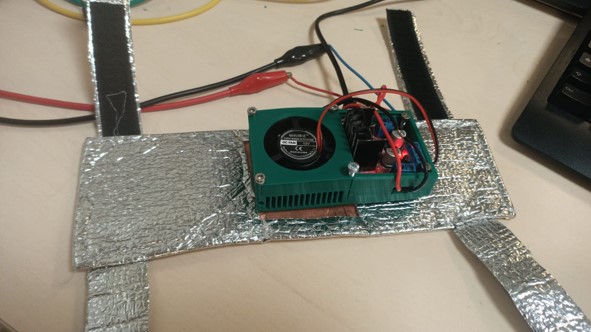

To maintain a constant temperature on the reference side of the module (i.e., the side not in contact with the user), we initially used a small heatsink and a 4 cm x 4 cm fan. This solution allowed for a truly modular system, with only the power supply shared across the modules. However, these small fans were not powerful enough and produced excessive parasitic vibrations, which could negatively affect the user’s haptic experience.

Consequently, we decided to delegate the cooling to a single large heatsink, equipped with three 120 mm fans mounted on the back of the vest. These large fans operate at lower speeds, allowing them to dissipate a substantial amount of heat while minimizing noise and vibrations. To connect the thermal modules to the back-mounted heatsink, we chose a water-cooled thermal bridge. The use of flexible tubing and a circulating water flow enables efficient heat transfer from the thermal modules to the central heatsink without significantly restricting the user’s range of motion. Although the pump used for circulating the water inevitably generates some vibrations, efforts were made to mitigate these effects by using foam dampeners and placing the pump in the back of the vest, thus reducing any adverse impact on the user.

On the user-facing side, we opted to diffuse the cooling or heating through a copper strip covered with a copper-infused fabric. The copper strip serves to distribute the desired temperature quickly over a larger area than the 4 cm x 4 cm surface of the Peltier module. The copper-infused fabric provides protection to the user, preventing cuts or discomfort that could arise from prolonged contact with semi-rigid metal surfaces.

To achieve the desired temperature, a simple proportional control was implemented. As long as the temperature difference exceeds 10°C, the Peltier module operates at full power. When the temperature difference is smaller, the power supplied to the Peltier module is reduced. Once the Peltier module reaches the target temperature, it is maintained at 30% of its power to slow down any heating or cooling. The system’s response time is sufficiently slow, resulting in an average overshoot of approximately 2°C.

Communication and Control Architecture

To manage all the thermal modules, we developed a modular solution that allows for adding or removing modules without modifying the code. Within the vest, all modules are connected in an I2C network, controlled by an ESP32 microcontroller acting as the network master. Each module functions as a slave with its own unique address. During the initialization of the vest, the master ESP32 establishes the I2C network and identifies all the connected slave modules. The master ESP32 then continuously queries each slave to retrieve its temperature. When a temperature command is received, the master ESP32 communicates the corresponding command to the appropriate module.

For communication between the user’s computer and the vest, we implemented aWiFi bridge between the ESP32 in the vest and another ESP32 connected to the PC via USB. The application on the computer communicates via USB serial with the ESP32, referred to as the base station. The base station generates a privateWiFi network to which the vest connects. Each ESP32 hosts an HTTP server to handle HTTP requests. The base station receives requests regarding the temperature settings for the modules, while the vest receives commands to adjust the temperature of the modules accordingly.

The choice of a WiFi bridge between the two ESP32 devices ensures reliable and stable communication.We opted for a wireless solution to reduce the number of cables connected to the vest, thereby enhancing user comfort and mobility.

Performance and Safety Evaluation of Thermal Modules

To evaluate the capabilities of the vest, we constructed two thermal modules. The Peltier element, at full power, is capable of reaching temperatures as low as 0°C and as high as 50°C. To ensure user safety, a software limitation has been implemented to prevent the temperature from dropping below 10°C or exceeding 40°C. Even if a higher command is given, the modules will not allowthe temperature to go beyond the safe limits. In the event that the temperature does exceed these boundaries for any reason, the ESP microcontroller in the vest enters a safety mode and halts all operations except for the water cooling system.

Regardless of the command given to the modules, all of them are able to reach their target temperature within a tolerance of ±1°C in under 30 seconds. The greater the initial temperature difference, the longer it will take for the module to reach the desired temperature.

Now that our solution has been validated with two modules, the next steps involve fabricating the remaining modules and integrating the vest into a virtual reality application. This will allow us to assess the vest’s ability to enhance the immersive experience by providing thermal feedback that corresponds to the virtual environment. Future work will also include optimizing the ergonomic design of the vest to ensure comfort during extended use. We will also investigate the integration of more advanced control algorithms to improve the responsiveness and stability of the thermal modules, potentially incorporating adaptive feedback mechanisms that respond dynamically to user interactions within the virtual environment.

Conclusion

In conclusion, this chapter has explored the design and development of a thermal haptic vest aimed at enhancing user immersion through environmental thermal feedback. By leveraging Peltier technology, we successfully created a modular solution capable of generating temperature sensations that reflect virtual environments, whether they be cold, like a snowy landscape, or warm, like a desert. Our work has validated the feasibility of providing localized temperature modulation in a wearable format, allowing users to experience a deeper sense of presence within virtual settings. We also addressed critical aspects such as safety measures, control system integration, and the scalability of the thermal modules.

Looking ahead, our future efforts will focus on refining the vest’s ergonomic design and conducting extensive user studies to assess the effectiveness of thermal feedback in enhancing VR experiences. The next chapter will shift focus to another aspect of haptics: vibro-tactile feedback. Specifically, we will explore how music can be transformed into haptic feedback, providing a unique way to feel sound through the use of wearable devices. This new approach aims to further expand the sensory dimensions of virtual environments, allowing users to not only see and hear but also feel the rhythm and vibrations of music.